Our Software —

EXAKT: Condition-based Optimization Software

EXAKT FACT SHEET

To Order

Introducing EXAKT into Your Operation.

What’s Involved?

EXAKT, a development of the Centre for Maintenance Optimization

and Reliability Engineering (C-MORE) at the University of Toronto,

is finding acceptance in the commercial world as an answer to

obtaining reliable predictions of failure in machine parts and

assemblies.

EXAKT collaborations through C-MORE have taken place with

Syncrude, Irving Pulp and Paper, U.K. Ministry of Defence, Zachry

Construction, Teck Resources, TransCanada Pipelines, EDF (French

nuclear power generation), Hydro One Networks, and XEROX.

This webpage is designed to provide, to enquirers, the answers to

a number of typical questions related to the implementation of

EXAKT. We think it will succeed in that regard, but we also invite

you to contact us further for any additional information you’d like

to have.

A Typical Company Situation

Many organizations undertake extensive condition monitoring of their fixed

and mobile assets. With the wealth of data being captured they may wish

to test the role of condition based maintenance software (EXAKT) to

optimize their maintenance decision-making.

Organizations often wish to analyze data from condition monitoring data

acquisition systems such that they can take optimal hazard/cost decisions.

EXAKT can be used to define which co-variates (key risk factors, i.e.,

measurements) are important to measure on line by these condition

monitoring (CM) systems to detect impeding failure from various failure

modes.

To compliment the insights that can be obtained from an organization’s

condition monitoring measurement system they often wish to enhance

maintenance decision making through proactively using this data in the

EXAKT software to optimize equipment performance — such as through

maximizing equipment availability or minimizing total cost.

To achieve this data is extracted from the condition monitoring databases,

to be combined with work order data (usually contained in a computerized

maintenance management system (CMMS)) to perform various conditionbased

maintenance analyses in EXAKT.

A Common Approach to Using EXAKT

Information Regarding Extraction of Condition Monitoring Data for

Fixed and Mobile Assets.

This document provides a high-level summary of what should be extracted

from the condition monitoring databases, to be combined with work order

data to perform various condition-based maintenance analyses in EXAKT.

It is not possible at this stage to advise on exactly which signals to extract. Any signal plausibly related to equipment failure can be extracted. It is better to initially extract too many signals than to extract too few and miss

a key risk factor by accident.

The extracted data will consist of a list of records. Each record will be

identified by a unique equipment ID, the record date, the working age of

the equipment, and any number of condition-monitoring readings recorded

at that moment.

The following sections provide information on these topics:

-

EXAKT implementation including process flow, implementation

time, implementation requirements, and documentation

- Regarding KPI for effectiveness of EXAKT outputs

EXAKT Implementation

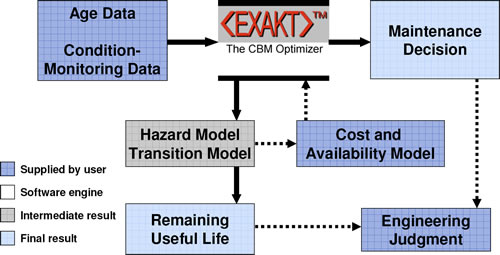

A high-level description of the basic required inputs and possible results is

summarized in the following diagram:

An EXAKT implementation consists of the selection of a fleet of similar

units to analyze, the processing and analysis of data associated with the

fleet, the development of appropriate models, any IT modifications

required to corporate databases with EXAKT installations, and all training

and support on software use and interpretations. The selection of a new

fleet of equipment constitutes a new implementation, with possibly much

lower IT and training requirements.

EXAKT consists of two modules: EXAKTm for modeling, and EXAKTd for

decisions. EXAKTm contains routines for data analysis, assessment,

correction, and modeling, and requires substantial training and experience

to use. EXAKTd is used to produce outputs such as remaining useful life

and optimal maintenance decisions using an established model and the

latest available data, and requires a smaller amount of training to use.

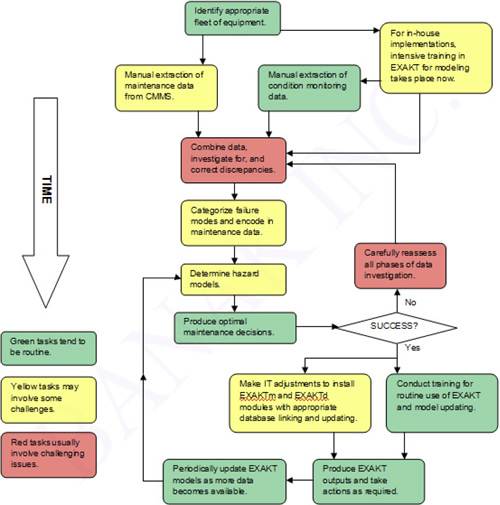

The following is the process flow of an EXAKT implementation:

An appropriate equipment fleet must be selected. The equipment must

have historical data available on installations and removals of components,

and this equipment should have been subjected to condition monitoring

(CM).

The initial analysis is conducted on data extracted from CM and CMMS

databases. The extraction of CM data is usually more straightforward than

the extraction of CMMS databases, as the latter database depends more

on human intervention than the former.

Data from these sources are combined and assessed for errors and

discrepancies. This is the phase of analysis that can be the most difficult

and time consuming, depending entirely on the quality of the input data.

Next, an assessment of the failure modes must take place. Similar failure

modes should be identified to be analyzed together, and the probably

relationships between CM data and failure modes should be established.

Once the data are suitably cleaned, hazard modeling can take place. This

process can be straightforward unless the CM data contains a very large

number of variables or the relationship between CM data and failures is

somehow complex. A suitable hazard model is identified for a particular

failure mode. This model will provide the key covariates correlated to

failure and an estimate of any ageing effect remaining after the covariates

have been accounted for. Then:

- EXAKT will model how the covariates change in time.

- Using the hazard model, the covariate change model, and information

relating to the cost of failure and the cost of performing preventive

maintenance, EXAKT can compute the optimal maintenance policy, as

described in points 3 to 5 below.

- A maintenance policy is defined as: the hazard rate level at which a

preventive removal should occur. The optimal maintenance policy is

one that achieves the best balance of failures allowed to occur and

preventive removals, where “best” depends on the desired criteria.

Two common criteria are: minimizing total cost, and maximizing

availability.

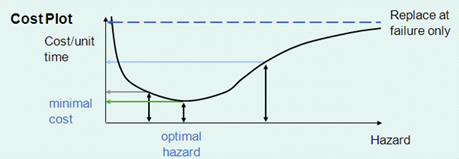

- The expected total cost (or maximum availability) resulting from a

particular hazard rate level that defines a maintenance policy is

computed by EXAKT. An example plot of costs associated with various

hazard levels is:

-

The optimal hazard rate is identified by the minimum cost. This optimal hazard rate

defines the optimal maintenance policy. In EXAKT, the optimal maintenance policy is

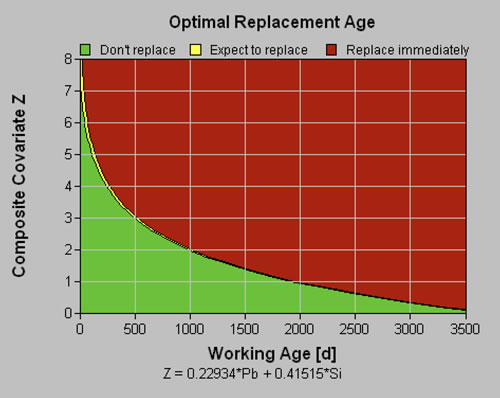

displayed in an easy to use decision chart that incorporates the key covariates, the

age of the equipment, and the cost information, as illustrated in the following

example:

When updated values for the key covariates (in this case, lead and silicon)

become available, EXAKT will plot the point corresponding to the age of

the equipment and the weighted values of the covariates. If the point

lands in the green zone, it is not yet time to perform preventive

maintenance. If the point lands in the red zone, it is time to perform

preventive maintenance. (If the point lands in the yellow zone, it may be

time to replace before the next inspection occurs.)

It cannot be guaranteed that there will be useful predictions from data

analyzed using EXAKT in a particular case. The lack of a suitable model

can result from any subset of the following causes:

- the CM data is simply a poor predictor of the failures.

- one or more data sources was of very poor quality or otherwise

insufficient.

-

one or more data sources was not properly assessed before modeling

took place.

A careful reassessment of the date would have to take place to determine

the next course of action, which may involve more modeling or a selection

of a different equipment fleet.

When suitable models have been identified, technicians and engineers

need to receive some training (see section Error! Reference source not

found. below) on the routine use of

EXAKT, including how to periodically update models when enough new

data become available.

At the same time, any IT installations and modifications should take place

in preparation for a full implementation. The EXAKTd module for decisions

should be installed on any computer used by engineers and technicians

needing access to EXAKT outputs. The EXAKTm modeling module should be installed on computers where model updating will take place.

EXAKT can read data from any ODBC source, so in principle it can be easy to set

up the required data connections, with perhaps some straightforward SQL

programming required. BANAK would undertake the programming details

within EXAKT. The details of a site’s IT infrastructure can result in the

following challenges:

- database security may make it inconvenient or impossible to set up

simple ODBC connections from any EXAKT installation to the data,

requiring more programming work to extract data securely. This work

can be handled by BANAK.

- in such cases extra programming work may be required of the CMMS

or CM database OEM, which could result in the need for intellectual

property agreements or amendments. These agreements or

amendments could be handled by BANAK.

1. Possible Condition Monitoring Data

The only limitation on what can be used as a condition-monitoring (CM) variable is

that it has the possibility to be expressed as a number. Most CM data is already

recorded numerically. Some categorical or descriptive data would have to be coded

is dummy (0-1) variables. It might prove challenging to translate free-form text

comments fields into a numerical format. Raw vibration signals typically require preprocessing

before being used in EXAKT.

Some CM data might be considered as measures of working age rather than true CM

readings. For example, fuel consumption rate is normally under control of the

operator who chooses the rate at which to do work.

In theory there is no limit to the number of records being analyzed; however,

computation speed may become slow on extremely large datasets (hundreds of

thousands of records). CM data recorded by sensors in near real-time can result in

datasets that are too large to be practically analyzed. In such cases some

engineering knowledge should be applied to the processing of these readings before

analysis within EXAKT. For example, if a common failure mode of interest is thought

to be preceded by a gradual loss in oil pressure, then an average oil pressure

reading over, say, one hour might be used, rather than a near-real time reading

resulting in thousands of largely redundant second-by-second readings.

Some initial processing of near-real time data would be done outside of EXAKT using

any suitable general purpose software.

EXAKT is usually best suited as a maintenance planning tool, and not a real-time

monitor of failures with very rapid onset. For example, a rapid decrease in some

pressure reading followed by a failure only a few seconds later may be difficult to

model in EXAKT, because EXAKT builds models relating CM measurements with

maintenance records. Maintenance records tend not to be accurate down to the

second. EXAKT cannot provide models that are more precise than the data used to

build them. Certainly, once EXAKT has determined a good model, it can then be

used in conjunction with online monitoring.

2. What Should Be Extracted Initially from CM Databases

EXAKT works by combining data from multiple sources. So it is essential that units

be identified in the same way from each source. It is also essential that each source record unit’s working age in the same manner. If this is not the case, some

modifications of the data must take place outside of EXAKT.

Data should be extracted into a standalone database first, for some processing

before being used by EXAKT. (Once models are constructed EXAKT can simply

access the raw data directly – by this time it will have been determined precisely

how EXAKT will be using the data.)

We call the unique identifier of a piece of equipment the Ident. The date on which

any reading or maintenance action takes place is the Date. The working age of the

unit is called the WorkingAge.

The raw data may contain other fields which may assist in the identification of units

and can help in ensuring data from different sources of data are combined correctly,

even if they are eventually not used by EXAKT. At this point it is always better to

keep more data rather than less. Call these miscellaneous identifiers Id1, Id2,….Finally there will be the CM readings themselves. They can be any reading that is (or

can be expressed) as a number and is plausibly related to the health of the

equipment. Call the CM readings at any particular time cm1, cm2, cm3,….

Then a typical record will look like this:

Ident Date WorkingAge Id1 Id2 … cm1 cm2 cm3…

The first row would contain suitable headings, ideally with the first three

called “Ident”, “Date” , and “WorkingAge”, but this is not necessary at this

point. The other headings should be short but informative and contain only

numbers and letters, if possible and convenient. But everything can be

changed if necessary.

IMPORTANT NOTES:

- Essentially: there is no reason to limit the number of signals to extract,

unless there are some clearly irrelevant ones. The "width" of a dataset is

not a problem. The length can be a problem with process data (near realtime)

and would have to be addressed outside EXAKT if necessary, as

EXAKT isn't suited to millions of records.

- The biggest problem is likely to come from aligning the data from the

CM data base and the CMMS.

- There is a possibility that no good EXAKT model can be found. For

example, in a recent study it was found that oil sampling gave no useful

prediction of part failures. The company representative subsequently

wrote: “The conclusion looks like being that we are wasting our time doing

oil analysis as it doesn't seem to reliably catch any failures, not even those

that are attributed to it.

I believe that this aspect of EXAKT, helping you not do activities that add

no value is under-rated as in “my organization” we do lots of activities just

because we have always done them, not because they add value.”

KPIs for assessing EXAKT performance

During the training phases, users of EXAKT will learn what the models are

intended to achieve and therefore how to measure their effectiveness.

It is important to understand that an EXAKT model is not usually used to

classify equipment into “good” and “bad” states. The optimal decision

output provides the optimal time at which to do maintenance given the

data used to the produce the model, current data readings, and

information about the relative cost of performing preventive maintenance

versus allowing equipment to fail.

An optimal decision requires a tradeoff between unnecessary preventive

work and missed failures. If a failure is ten times as expensive as

preventive work, one would expect to make some unnecessary preventive

removals. If a failure is only twice as expensive, some failures should be

allowed to occur. These occurrences are not shortcomings of EXAKT and

its models.

The way to determine if an EXAKT model is effective is to determine how

well it actually fits the data. There are techniques to assess model fit

during the modeling phase itself. In the long term, the following steps

should take place periodically to monitor the ongoing performance of the

models:

- Assess how the model behaves on the data used to produce the

model. How many failures occurred? How many preventive removals

occurred? How much useful life does each asset enjoy? This

establishes a benchmark.

- onitor the performance of the model as data are collected and more

failures and/or preventive removals occur. Are failures and removals

occurring at the same rate? Is a similar amount of useful life being

enjoyed? Are predictions of remaining useful life accurate over the

short term?

How BANAK can Support an Organization’s Objectives

A Typical Implementation

Site visit by a BANAK consultant to collaborate with a company’s

condition monitoring staff and maintenance engineers to establish data

acquisition protocols and the transfer of data electronically to BANAK in

Toronto, and to discuss the content and meaning of the data contained

in the condition monitoring databases and CMMS systems. (Typically 2

days travel + 4 days at site)

Analysis of condition monitoring and CMMS data for a selection of

equipment:

5-20 days in Toronto depending on data quality and number of

equipments being analyzed.

Site visit to: Present to company’s condition monitoring engineers the

results of the equipment analysis including identification of any measurements that are highly correlated with different failure modes

(Typically 2 days travel + 4 days at site).

Expected Duration of Assignment (First Phase)

A typical estimate of consulting days for this work is: 17 - 32.

Deliverables to Client

- EXAKT model development as described in “A Typical

Implementation” above: 17 – 32 days.

- EXAKTd for Company: cost USD 35,000 for one license or USD 50,000 for up to five users.

- Training for EXAKTd: 2 days.

- EXAKTm for Company: cost USD 50,000 for one license

- Training for EXAKTm for routine model updates: 1 day.

- If the result of the assignment is considered successful by a

company then BANAK shall provide a second proposal for the

implementation of EXAKTm + training + advisory in the

development of the data cleaning and modeling for other CM

techniques.

A Closing Suggestion

Thank you for your interest in EXAKT. We trust this brief coverage

will have provided much of the information you were looking for.

We understand that your decision to adopt EXAKT is an important one

in several respects. The commitment is substantial in terms of time,

money and effort. That’s why we would be most pleased to answer

any and all additional questions you may have, personally, by

telephone.

Please call us at your convenience. If we’re not reachable at that time

we will call you back. We want to ensure that you are totally

conversant with all aspects of your EXAKT adoption. Call me at

Canada Code 1, 416 234 8558. Or e-mail me at

jardine@mie.utoronto.ca

Andrew Jardine

|